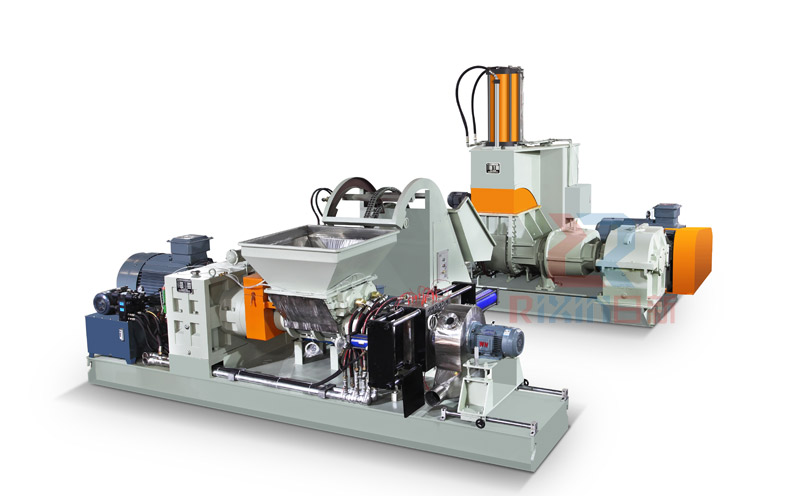

The newly invented rubber filter for the provincial opening mill adopts a double feeding device. Ït is widely used in cable industry, reclaimed rubber industry, inner tube industry, rubber hose industry and plastic runway.Such as rubber products manufacturers. Mixed rubber can be made by internal mixer, without the need for the old process through the opening machine strip feeding into the old filter, can be directly fed into the double-pull glue feeder.Structure. By using screw pushing and conveying, impurities in mixing rubber or reclaimed rubber can be removed or extruded or granulated. Mainly by the lifting feeder, the rubber feeding mechanism,Screw, barrel, glue filter head (discharging head, granulating head), automatic glue cutting device, temperature control system and transmission device, etc.

1. The glue feeding filter has good feeding effect and strong filtering ability, which greatly reduces the working intensity of workers and the investment cost. Compared with the old model, it reduces labor intensity and reduces investment cost.

2. Hydraulic switching device, fast operation, no glue leakage, time saving and labor saving.

3. Electric control system uses frequency converter to improve resource utilization and energy saving.

4. Adopt special reducer for hard tooth extruder, with low noise and long service life.

5. Material barrel and screw are made of high quality alloy steel 38CrMoALA, Quenched and tempered and nitriding, wear resistant and durable.

б. The perforated plate is used to support the filter screen and is the discharge port. It is a conical hole expanding along the direction of the rubber material flow, which saves energy and does not burn glue.

The newly invented rubber filter for the provincial opening mill adopts a double feeding device.

DOWNLOADS